DIY 3D Printing Filaments

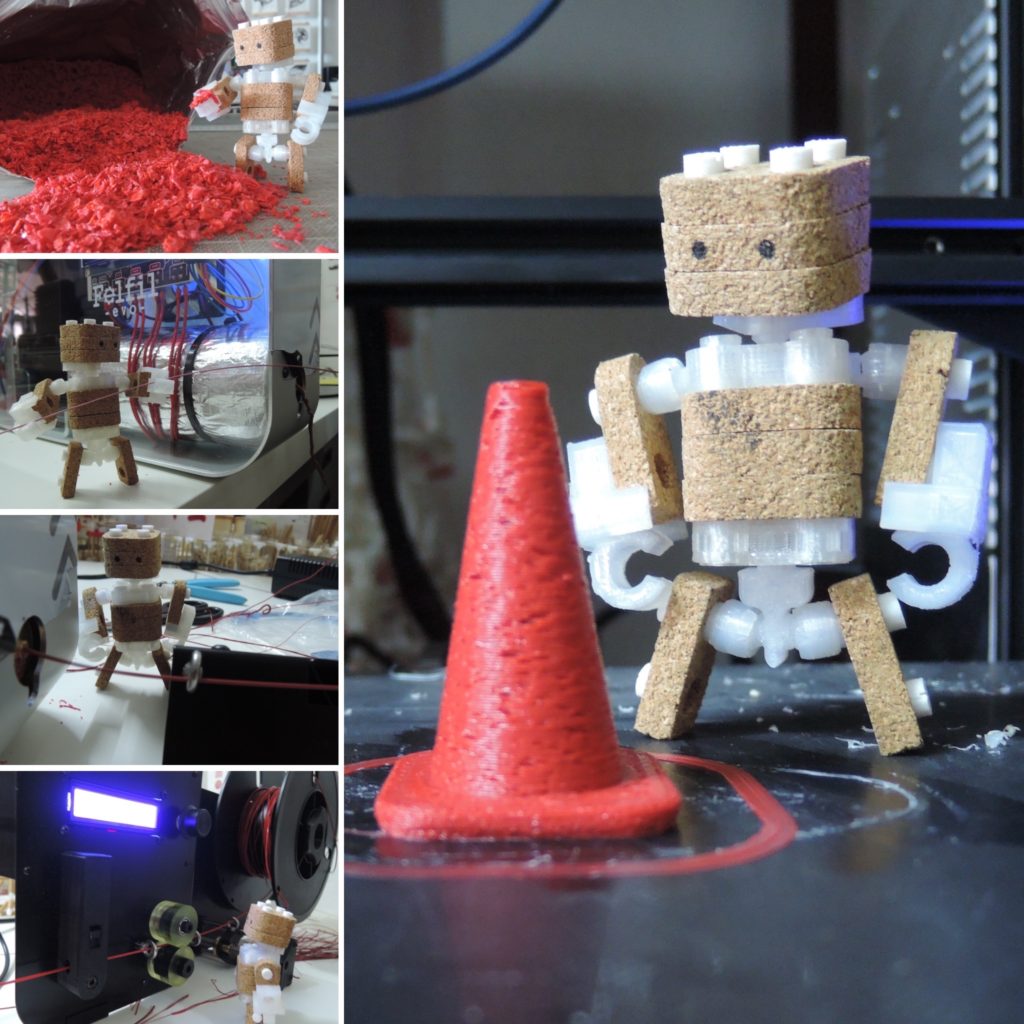

Sustainability has been one of our studio’s top priority since its establishment in 2014. Since we started experimenting with 3D printing early on, the amount of failed 3D prints have been piling up higher and higher. In an attempt to recycle the plastics, we invested in a system from Felfil that could help us recycle the plastic off-prints into 3D printing filaments again.

The plastic off-prints were first shredded by our friends from Plastic Wood Studio. It then took us a couple of days to unbox and setup the Felfil extrusion system. After testing with the PETG pallets that shipped with the machines, we finally tested the shredded PLA plastics. It took a few dedicated hours of fiddling with the different machine settings before we could reach a relatively consistent filament extrusion and spooling. We test printed the recycled filaments the next day. Though the resulting print was not as flawless as that from virgin PLA filaments, we believe that can be improved if we had more time with the experimentation.

All in all, we consider this brief initial testing of PLA recycling a success but yet leaves much room for improvement. It’s unquestionably one big step forward for our studio’s unwaivering sustainability goal!